September 9, 2024 by Mark Tweedie

Digital Transparencies for Photopolymer Gravure

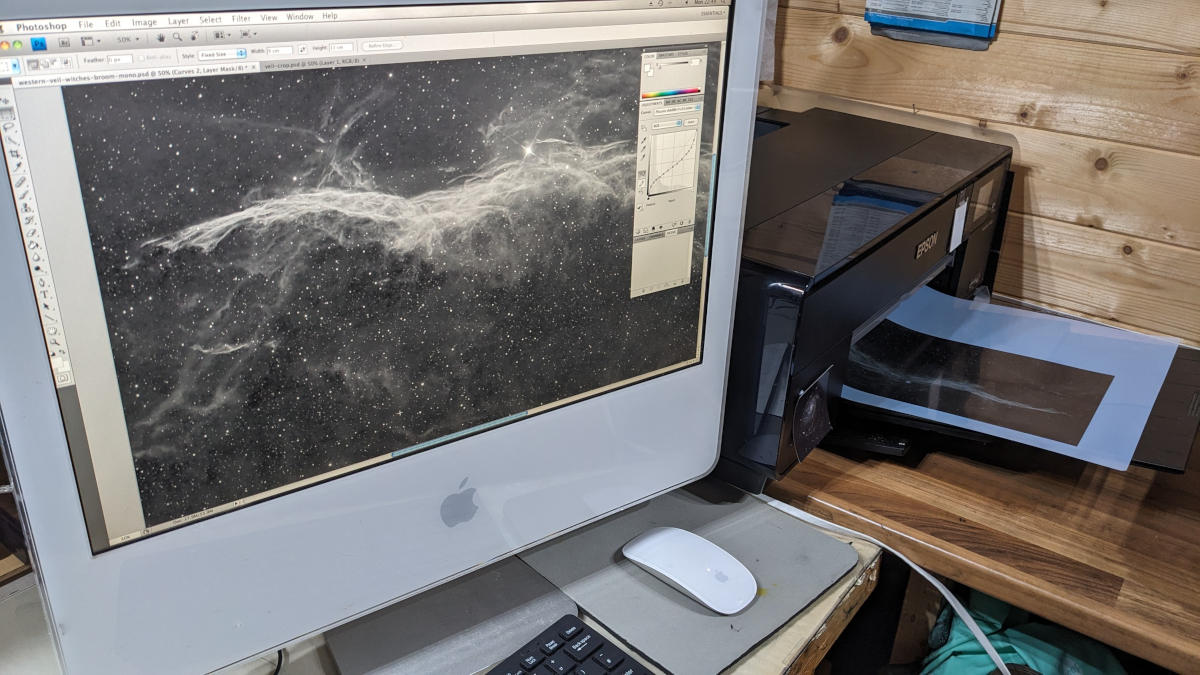

I am frequently asked about the processes behind a photopolymer gravure. Having chosen an image and worked it in the usual way in your graphics package, the next step is to modify the image by the application of a previously-established Photoshop curve and then to print a digital transparency. This will reduce the inherent contrast of the digital output and effectively “squash” the extreme light and dark regions. Polymer plates cannot handle the high native contrast ratio of an unmodified image and it is necessary to reduce the range at each end of the contrast curve at the point of outputting it to the printer.

Once the transparency is dry, it can be used in a UV exposure unit to make a printable impression on a steel-backed photopolymer plate which is then washed out, dried, inked and passed through the etching press.